The term vacuum double glazing might confuse many people, as some assume that there is a vacuum between the glass panes cavity of any window with double glazed units.

But as a matter of fact, the conventional, energy-efficient Low-E double glazing has quite the opposite of vacuum physics. The standard double-glazed unit has inert gases between two glass panes or just air.

The seals around the edges of the glass panes and spacer bars do not let the gas escape, but over 3-10 years, regular gas-filled double glazing loses most of its insulation performance due to gas leaks.

So you might ask now, what exactly is a vacuum insulated glass (VIG), how is it different to the standard double glazing we all used to see in our homes and why this glazing technology is the future of the next generation of highly efficient windows.

Vacuum double glazing has the same panes of glass separated by a gap, but instead of gas or air in between them, it has a vacuum. The vacuum has very low thermal conductivity and thanks to its highest thermal insulation coefficient.

A vacuum is an excellent thermal barrier, which will stop cold or hot weather from entering your home drastically.

The fundamental physics of how a vacuum function dictates the design of vacuum-glazed units.

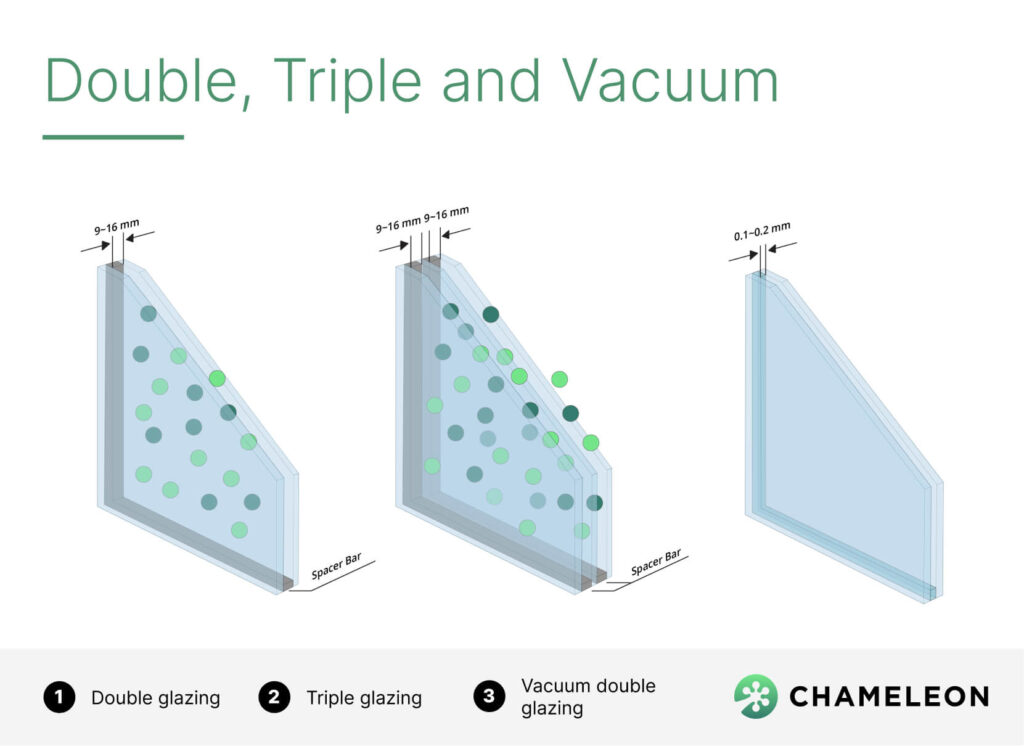

Unlike inert gases, a vacuum creates high atmospheric pressure by removing all gas molecules between two glass panes. This pressure difference causes the external air to push the glass panes inward, pulling the panes together.

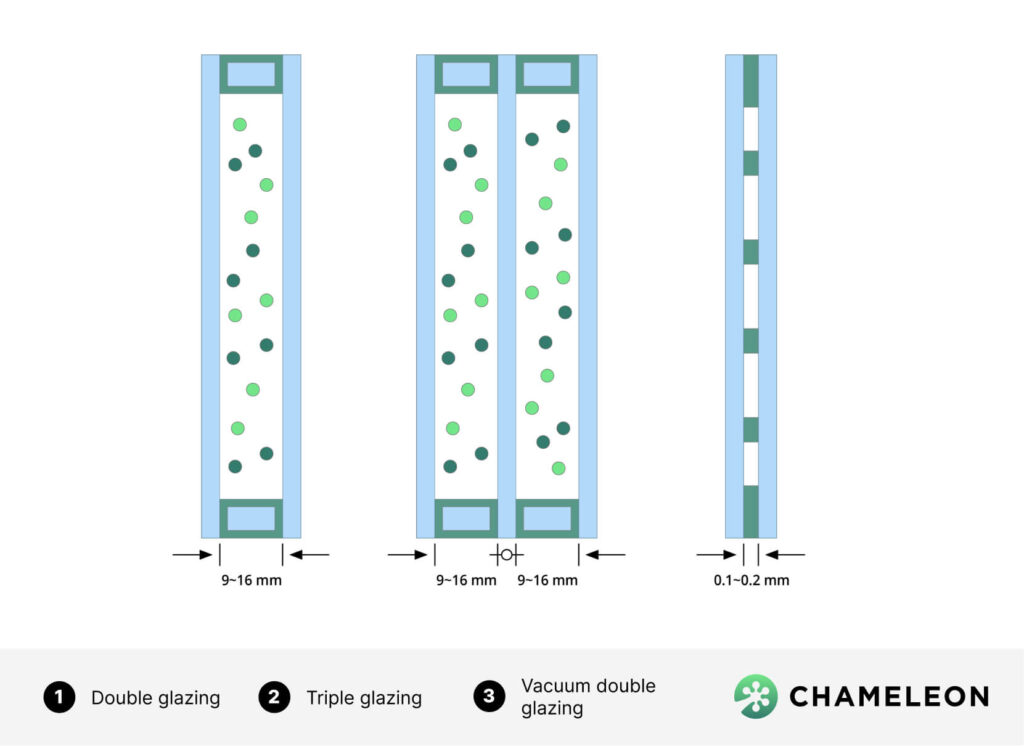

To prevent the glass panes from bending and touching each other at certain points, micro-spacers (also called supportive pillars) were introduced into the design of vacuum double glazing.

These tiny pillars spaced throughout the unit resist the atmospheric pressure, creating a small, consistent gap between the panes and enabling the vacuum environment to be maintained.

The micro-spacer design is critical for allowing vacuum glazing to utilize the thermal performance benefits of the vacuum while maintaining the unit’s structural integrity.

The concept of vacuum-insulated glass (VIG) was first described in 1913 by German scientist Zoller. However, it took many decades for the technology to be further researched and commercially developed.

In the mid-1980s, research into VIG resumed in the United States and Australia. The University of Sydney in Australia conducted pioneering work on the feasibility and methods for producing vacuum glazing. In 1996, the first commercial VIG product was produced in Japan utilizing research from Sydney University.

A major milestone was reached in 1997 when the first commercial production of VIG was launched, over 80 years after the initial concept was proposed.

Since then, advancements in materials science, vacuum technology, and manufacturing processes have enabled steady improvements in the performance and viability of VIG. While early adoption was limited, VIG is now poised to become a leading technology for highly insulating windows and facades.

Continued development and increasing demand for energy-efficient buildings are driving broader utilization of vacuum-insulated glass.

One of the primary applications for vacuum double-glazing units is in historic building restoration projects. In these projects, existing single-glazed windows are retrofitted with vacuum glazing to improve thermal performance and prevent heat loss, while maintaining the historic aesthetic.

The thin profile of vacuum units makes them ideal for fitting inside existing window frames, allowing the original sash and trim to be preserved. This avoids major modifications to the window openings that could alter the building’s historic character. It also allows the original timber window frames to be retained rather than replaced.

By providing a thermally efficient upgrade that is sympathetic to historic architecture, vacuum glazing enables these landmark buildings to have modern energy efficiency while retaining their architectural heritage. This is especially important for historic sites where strict preservation standards may apply.

The minimal visual change achieved with vacuum double glazing makes it an excellent retrofit option over bulkier double or triple glazing alternatives.

Sash window retrofitting is one of the main and growing markets for vacuum glazing manufacturers. Retrofitting is one of the best alternatives to bulky secondary glazing.

Our company works in this marketer as a glass installer, but we also refurbish sash window frames as the part of sash window double glazing installation process.

Because of its use in window restoration projects and slime profile, vacuum double glazing also is called heritage double glazing.

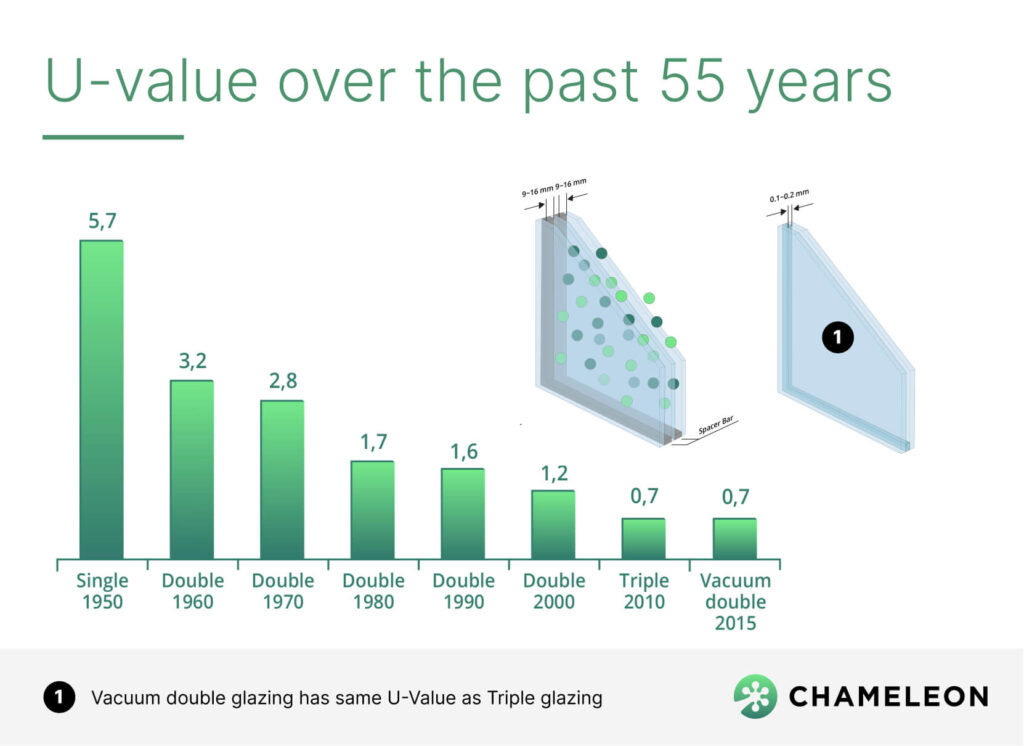

With vacuum insulated glazing units, old beautiful windows can be as energy efficient as triple-glazed windows.

Vacuum double glazing can also be used in secondary glazing where slim-profile and lightweight glazing is required by design. It can also be used as one of the panes of triple glazing. Some makers of bespoke windows use this slim-profile double glazing.

Like any product on the market, Vacuum glass has its own pros and cons, so it is important that you understand these before making a decision.

Pros

Cons

The main difference is in the spacer. Conventional double glazing uses a warm edge spacer, made of metal or composite materials and has a desiccant to absorb moisture. The most popular on the market is Super Spacer by Edgetech (a US company). This type of spacer conducts less heat than metal spacers. However, it still conducts heat.

The other difference is in the insulation of conventional double glazing, which uses gasses. Conventional double glazing uses argon or krypton gas for insulation. These gases have good insulating properties, but they are not as good as a vacuum.

More companies will start production of vacuum insulated glass; this will reduce the cost of vacuum double glazing and will make it more affordable. The energy cost will also make VIG a more financially viable choice for homeowners looking for ways to increase the thermal efficiency of their houses to reduce energy bills. More manufacturers will be using VIG glass for new windows.

Retrofitting of single glazing will only be done with vacuum glass; the standard gas-filled double glazed units will become obsolete for this task.

Reference: https://winsmart.eu/activities/vacuum-insulation-glazing.aspx

U-Value will drop to below 0.5 W as, during the last 50 years, the insulation capability of windows has significantly improved, and this trend will continue. U-value of window glazing will be close to the well-insulated wall.

The performance of glazing has changed over time. A well-insulated wall, for example, has a U-value of 0.15 W

Yes, if it is a vacuum double glazing (VIG), and no if it is standard double glazing.

The demand for slim double glazing comes from restoration projects, where single glazing is retrofitted.

The middle of double glazed windows is usually filled with argon or krypton gas or has a vacuum instead.