When it comes to removing old paint from windows during sash window restoration, the type of sandpaper you use can make all the difference.

The key is using the right grit and abrasive material to do the job efficiently without damaging the underlying wood or spending days on this task.

Here are some tips for choosing the best sandpaper for paint removal on windows and doors, along with a comprehensive guide that will make you an expert sandpaper buyer.

Sandpaper is available in a variety of types, distinguished by grit size, abrasive material, backing material, and sheet shape.

For removing paint, you’ll want to start with a relatively coarse grit sandpaper.

A P60-P80 grit is a good starting point as it will quickly remove the top layers of paint without gouging into the wood.

After the bulk of the paint is removed, switch to a P100-120 grit for smoother sanding before finishing with a fine P150-220 grit.

| Grit Level | Description | Grit Range | Particle Size (Microns) | Uses |

| Coarse Grit | Coarse grit sandpapers have a lower grit number and larger abrasive particles. | Typically between 40 to 60. | 425 to 250 microns | Removing material quickly. Stripping old paint or varnish from the wood surface. Smoothing rough surfaces. Shaping wood or other materials. |

| Medium Grit | Medium grit sandpapers fall in the mid-range of grit numbers and have moderately sized abrasive particles. | Typically between 80 to 120. | 190 to 125 microns | Further smoothing surfaces after using coarse grit. Preparing surfaces for painting or finishing. Removing smaller imperfections. |

| Fine Grit | Fine-grit sandpapers have a higher grit number and smaller abrasive particles. | Typically between 150 to 220 and above. | 100 to 68 microns (and finer for grits above 220) | Final smoothing before applying a finish. Sanding between coats of paint or finish. Polishing surfaces to a high sheen. |

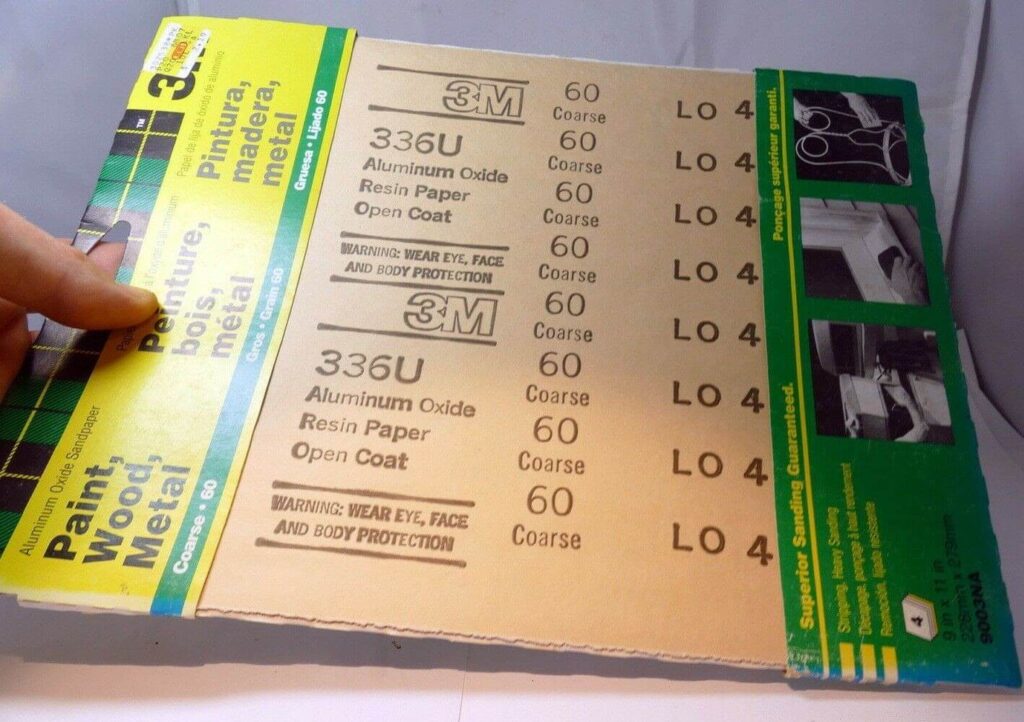

Coarse grit sandpaper refers to abrasive paper with a relatively low grit number, usually ranging from P40 to P60. The lower grit number indicates larger abrasive particles.

Key features of coarse sandpapers:

Coarse sandpaper is an aggressive abrasive designed for heavy stock removal where surface finish is not a priority. It provides fast smoothing, shaping and finish removal.

The Sanding Discs 125mm 8 Hole is a premium quality sandpaper designed specifically for woodworking and automotive applications. With its unique features and high-grade materials, it stands out as a top choice for professionals and DIY enthusiasts alike.

Reasons Why It’s the Best for Wood:

The Prodec Craftsman Green Aluminium Oxide Sandpaper stands out as a premium quality abrasive specifically engineered for woodworking applications.

Medium-grit sandpaper has a mid-range abrasive size that provides a balance of stock removal and smoother finishing.

Typical features:

With the right blend of abrasion and smoothing, medium sandpapers are versatile for most smoothing, surface prep and finishing steps.

Fine sandpaper grit refers to abrasive paper with a high grit number usually ranging from P150 to P400 and higher. The higher number denotes smaller abrasive particles. This grit is good for sanding wood fillers.

Properties of fine sandpapers:

Fine sandpapers provide the last step in smoothing prior to finishing or polish already finished surfaces without removing significant material. They are essential for surface prep.

The particles that give sandpaper its abrasive quality are made from different materials, each with its own characteristics.

Common abrasives used in sandpaper include:

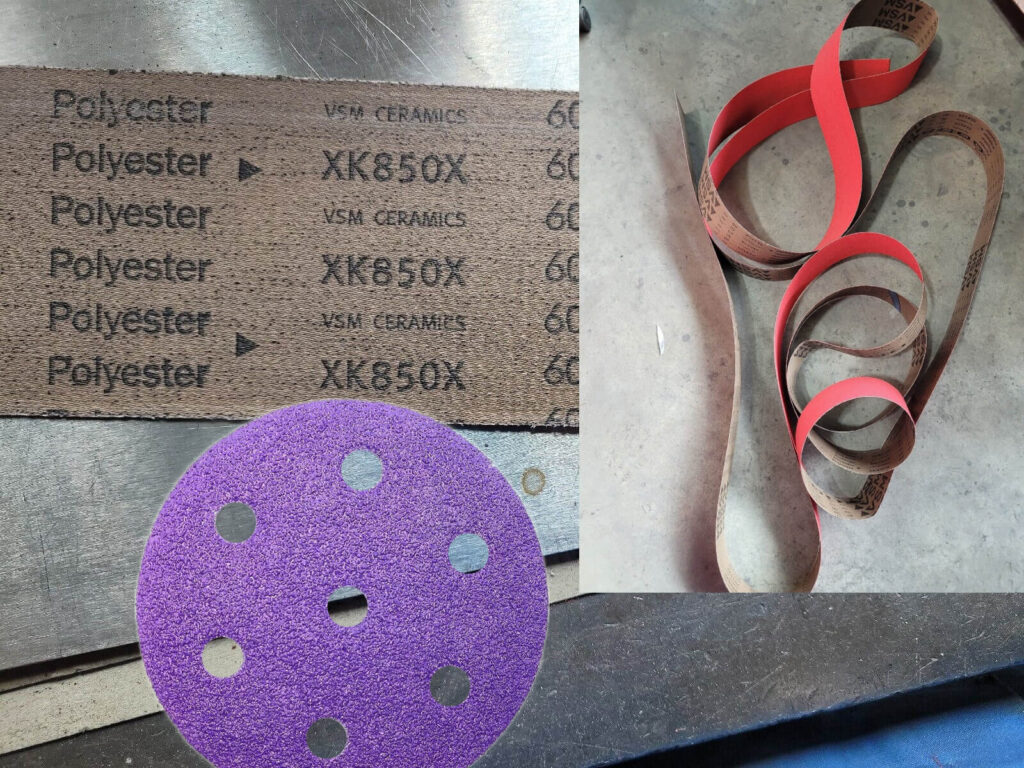

Ceramic sandpaper is a type of sandpaper made with ceramic alumina abrasive grains that have been heated and fused together into hard, sharp points.

The ceramic alumina grains are highly resistant to fracturing or dulling during use. This makes ceramic sandpaper extremely long-lasting compared to other abrasive types.

High Heat Tolerance – Ceramic alumina can withstand very high temperatures generated during aggressive sanding without degrading. This makes it well-suited for high-pressure and high-speed sanding applications.

Hard Material Removal – The sharp ceramic grains efficiently remove hard materials like paint, varnish, metal and hardwoods. The durability allows fast stock removal.

Aluminium oxide is one of the most common abrasives. It is harder than other materials like silicon carbide while still being affordable.

The aluminium oxide is manufactured by refining bauxite ores into a fine powder with very hard, angular grains.

Garnet is a natural abrasive mined from stones. It is relatively soft and the grains fracture to reveal new sharp edges.

This helps prevent clogging of the sandpaper. Garnet is an excellent abrasive for finishing work and smoothing surfaces. It leaves a fine scratch pattern. The softness makes it less ideal for bulk removal.

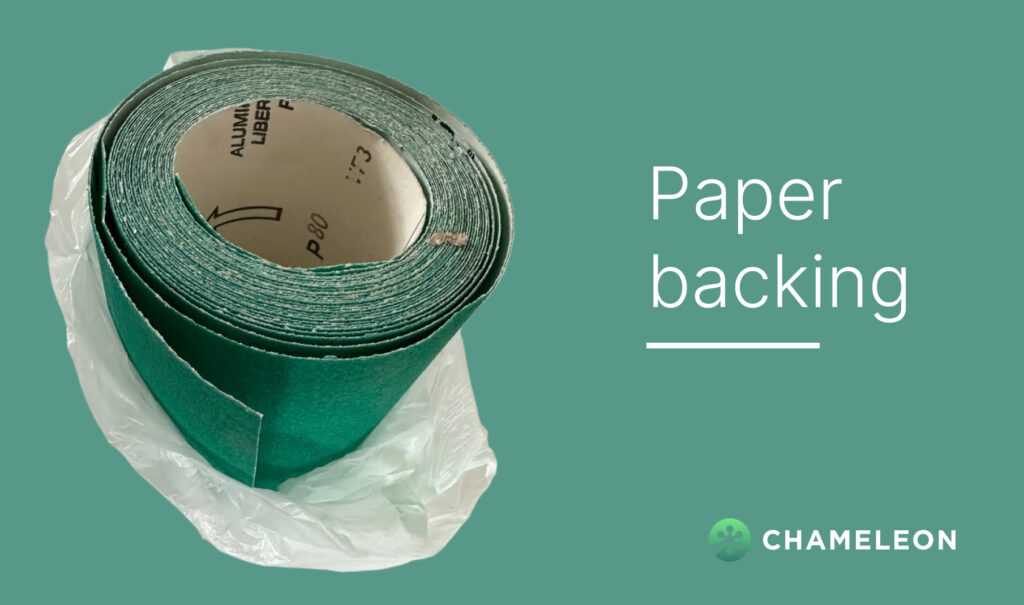

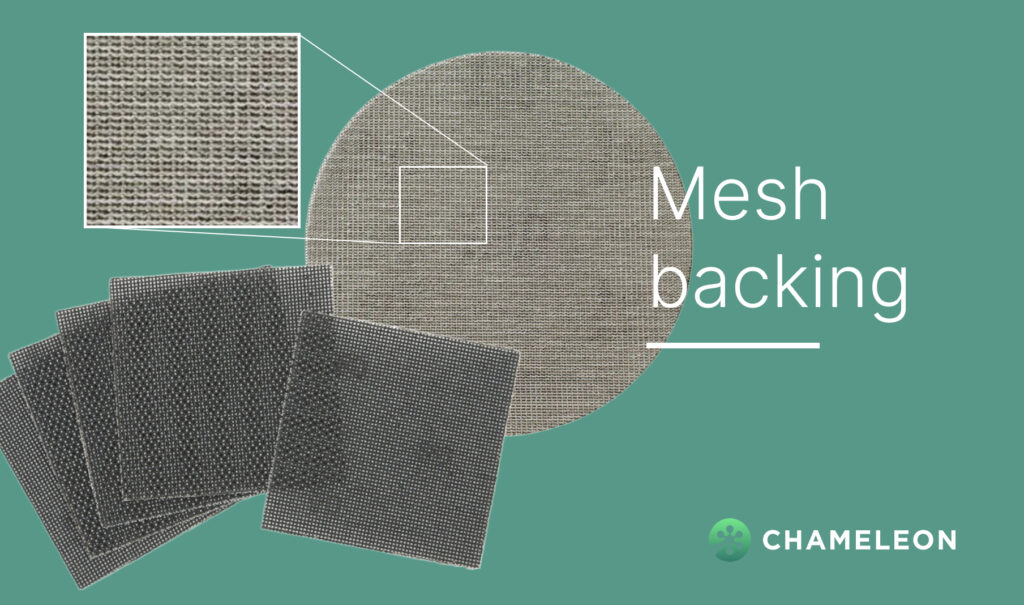

In addition to the grit and abrasive material, the backing material of sandpaper also makes a difference in performance.

Sandpaper comes with a variety of backing types, each with its own properties and ideal uses. Selecting the right backing is important to get the most efficient sanding action for your particular project.

The main options for sandpaper backings are:

Traditional paper backing is suitable for most sanding applications. It’s flexible and affordable. The main downside is that paper sandpaper can wear out faster than other materials when exposed to water.

Hook and loop-backed sandpaper contain tiny hooks and loops on the backside of the abrasive material that allows the sheets to be securely fastened to a compatible sanding pad.

Key product features include:

The main advantage of hook and loop backing is quick, easy grit changes. It offers a secure mechanical attachment without messy adhesive.

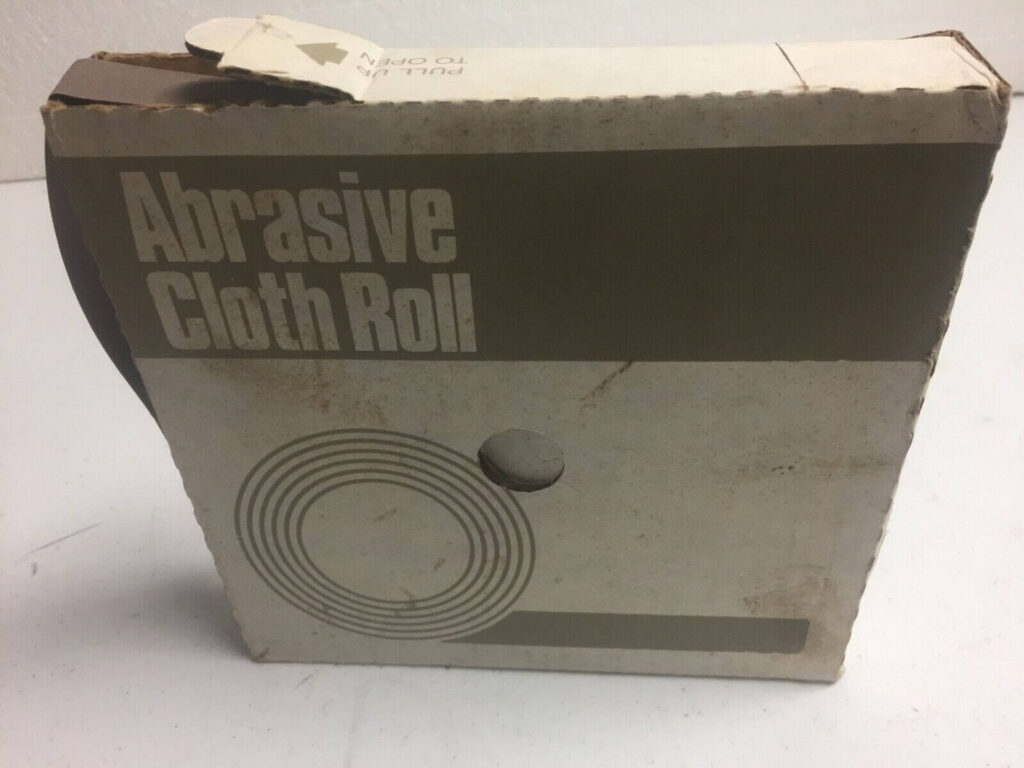

Cloth-backed sandpaper is very durable and resistant to tearing. It’s a good choice for extensive sanding jobs.

The stiff cloth backing allows it to be made into sanding disks for use with power sanders. The durability of cloth makes it well-suited for this high-speed application.

The downside is that the stiff cloth backing makes it a bit harder to sand contoured surfaces smoothly by hand.

Sponge-backed sandpaper is flexible and conforms well to curved surfaces like spindles and moulding. It can be a good option for detail sanding. The soft sponge wears down faster than other materials.

Mesh or net backing allows fine dust to fall through the holes so the abrasive doesn’t clog as quickly. This is ideal for power sanders. Mesh paper is very durable but less flexible.

When it comes to paint removal, sanding discs used with the best orbital sander like Festool can be the most efficient combination. The circular sanding discs allow the orbital sander to cover a larger surface area compared to sheets or belts.

The constant motion of the orbital sander prevents the abrasive from digging into the wood while still removing paint and varnish effectively.

Using progressively finer grit discs, starting with a coarse P80 and working up to a P220, allows rapid removal of old paint and varnish while smoothing the surface.

The orbital sander’s dust collection system also helps keep the sanding surface clear of debris for maximum efficiency.

With the right technique, orbital sanders and quality sanding discs can strip paint quickly without gouging the underlying wood.

Here is a step-by-step guide for using sandpaper grits to remove paint from wooden windows:

1. Start with coarse-grit sandpaper, such as 60-80 grit, to rapidly remove the top layers of paint and get down to the bare wood. Use firm pressure in the direction of the wood grain.

2. Once the top coat is removed, switch to a medium 80-100 grit paper to smooth away the remaining paint layers and any roughness. Use lighter pressure and sand diagonally across the wood.

3. When you’ve exposed the bare wood, continue smoothing with a fine 100-120 grit paper using light pressure. This will remove scratches and polish the wood surface.

4. Clean away all sanding dust with a tack cloth. This prevents the dust from gumming up the next grits.

5. For a very smooth sanded surface, do a final pass with 150-220 grit paper using minimal pressure along the wood grain.

6. Frequently change your sandpaper to expose new sharp abrasive. Fold sandpaper into a pad for easier grip.

7. On rounded frames or sills, wrap sandpaper around a soft sanding block to sand contours smoothly.

8. Always sand in the direction of the wood grain – avoid going across the grain which causes deeper scratches.

9. Finish by carefully hand sanding corners and edges with used sandpaper.

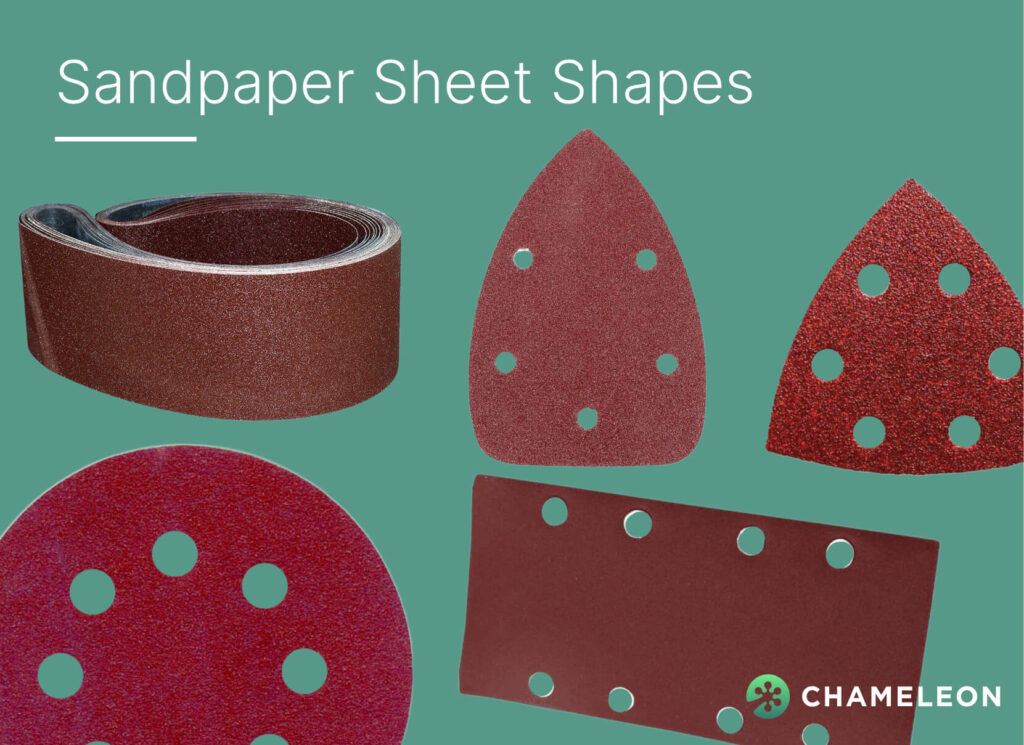

Sandpaper comes in a variety of shapes and sizes tailored for different sanding applications.

The sheet format affects the types of surfaces and jobs the abrasive can be used for.

Common sandpaper sheet shapes include:

Circular sandpaper discs are designed to attach to random orbital sanders, disc sanders, and other power tools. They come in a range of diameters. The circular shape allows for sanding contoured surfaces.

The sanding discs combined with an orbital sander like Festool are the most effective combo in paint removal tasks.

When sanding discs used on power sanders become worn out and smooth, they still can have some useful life left in them for hand sanding applications.

Rather than throwing the discs away, consider repurposing them for tight spots and detail work. Used sanding discs can be folded in half to expose fresh, sharp, abrasive grains along the crease.

The folded abrasive conforms nicely to curved profiles and corners.

The slightly duller grains, compared to fresh sandpaper, help avoid over-sanding or gouging profiles when working in tight areas.

Just take care to fold evenly and watch for thin spots.

With a light touch, used-up sanding discs can tackle detail sanding on ornate mouldings, curved table legs, picture frames, and other areas that are not easily accessed by power tools.

Additionally, reusing old sanding discs eliminates the need to purchase extra sheets of sandpaper for hand sanding.

Sanding discs come in two main varieties – with holes and without holes.

Discs with holes have a pattern of perforations that allow dust extraction and debris removal while sanding, especially when used with a vacuum system on power sanders. The holes prevent clogging of the abrasive grit. These are preferred for power sanding applications.

Discs without holes provide a continuous sanding surface and firm backing support. This can lead to smoother, more even sanding on flat surfaces. Hole-less discs are commonly used for hand sanding applications where dust extraction is not as important.

Rectangular sandpaper sheets in standard sizes, like 23×28 cm, are used for hand sanding. Large full sheets can be cut down as needed. Sheets allow sanding of broad, flat surfaces.

Sanding belts consist of a continuous length of abrasive-coated material that wraps around two cylinders on a belt sander. As the cylinders rotate, the belt provides a flat sanding surface for smoothing, shaping, and finishing wood and metal workpieces.

Narrow strips of sandpaper can be used to sand hard-to-reach areas. These strips are typically 2.54 cm wide and 30.48 cm long. Alternatively, you can use disks folded in half, as mentioned above in this article.

In addition to common sheets, disks and belts, sandpaper also comes in a variety of speciality shapes designed for specific applications. Some examples include:

Sandpaper is designed for either dry sanding or wet sanding applications. Each has advantages depending on the material and project:

Dry sandpaper utilizes abrasive grains that fracture off sharp points as they scrape across the material surface. This creates fine dust that must be cleaned up and can be hazardous to inhale, especially when sanding wood, paints, and composites.

Dry paper is best suited for general-purpose sanding of most materials using hand sanding or power sanders. The abrasive grains cut efficiently without any lubrication or fluid.

Wet sandpaper is designed with a waterproof backing that allows the abrasive surface to be lubricated with water, oil, or other fluids during sanding. This controls dust and improves the surface finish.

Wet sandpaper works by both abrasive fracturing and mild corrosion from the fluid. The slurry created helps keep the grains unclogged. Wet sanding produces a finer finish and maintains sharp grit longer compared to dry methods. However, wet sandpaper is limited to hand sanding applications due to electrical safety concerns.

In summary, dry sandpaper handles everyday general sanding while wet sandpaper excels for finish work where dust control, lubrication, and finer scratches are beneficial. Each has its own best applications.