In this article, we will look at the best multi-tool blades for Oscillating multi-tools.

Oscillating multi-tools are versatile devices that can cut, grind, sand, and polish a wide variety of materials when equipped with the proper accessory blades. We use this tool often while renovating timber frame sash windows or double-glazing sashes.

They work well for tasks such as cutting off some rotten parts of the window frame, unblocking painted shut windows, or replacing wooden sills.

Our team uses over 400 blades per year, so picking the best blades for us means a lot.

In this article, we will share our research and our pick of blades that we use.

If you just need to know which blade is best for your task and material, we’ve included that info at the beginning of this article. But if you want to really dive into oscillating tool blades, keep reading! By the end, you’ll be an expert when it comes to choosing the right blade.

For cutting sheet metal, steel pipes, nails, and other metal materials, look for bi-metal blades made from high-speed steel or carbide. These ultra-hard blade materials remain sharper longer than standard steel.

Optimal blade widths for metal range from 3/16 to 1 inch. Wider blades can overload the tool on thick metal. Choose a blade with a curved, tapered shape with gullets in between each tooth for swarf removal. A blade with 14 or more teeth per inch will provide a finer finish cut.

This bi-metal titanium multi-tool blade is perfect for cutting metal. It lasts 2-5 times longer than any other metal-cutting oscillating tool blade on the market, offering a great value-for-money ratio.

Compatible with the most popular multitool brands.

Pack of 5, which is more then enough for any DIY or even professional task.

The best oscillating tool wood cutting blades have a high tooth count. The most common blade used for wood is the Japanese tooth blade, thanks to its precise and clean cut. Wood cutting blades typically have between 16 and 22 teeth per inch, which allows for smooth, splinter-free cuts in natural and engineered wood materials.

Blades made with bi-metal materials, as is the case with blades for cutting metal, will also last longer when used for cutting wood. Bi-metal blades cost more initially, but you need to replace them less often, so they can be more economical in the long run. Bi-metal blades are great for wood cutting because you don’t need to worry as much if you accidentally hit a nail while cutting through the wood.

Blade widths ideal for wood range from 1 to 2 inches. Look for a blade with an aggressive, wavy set tooth pattern optimized for quick, tear-out-free cuts across the wood grain.

Compatible with Bosch, Chicago Electric, Dewalt, Dremel, Fein, Makita, Milwaukee, Porter Cable, Ridgid, and Ryobi brands. This pack has different blade sizes, which is perfect if you work with wooden windows and furniture.

It has one blade with Bi-Metal Titanium, which is perfect for cutting metal as well as wood.

For removing tile, concrete, plaster, and masonry, choose a thick, rectangular-shaped carbide or diamond-grit-edged blade.

The flat blade profile exerts consistent pressure and minimizes gouging of the underlying surface.

Diamond-edged blades will maintain sharpness when scraping tile adhesives and grout. Blade widths from 1 to 2 inches work well to rip into grout lines and penetrate thick materials.

Made of high-carbon steel and diamond grit edge, this blade ensures durability and longevity, making it a reliable tool for heavy-duty tasks.

Compared to other blades in the market, this multitool blade offers superior performance at a competitive price, ensuring value for money.

Designed to fit most oscillating tools, it’s compatible with brands like Dewalt, Milwaukee, and more

Picking the optimal multi-tool blade is key to having the right tool for any job. When selecting a blade, there are several factors to consider based on your intended use and the materials you need to cut:

When choosing replacement blades, one consideration is which material will have the greatest durability and last through prolonged use.

Most common materials for oscillating tool blades are:

In summary, bi-metal oscillating blades last the longest, maintaining sharpness and durability even during repetitive heavy-duty use. Carbide-grit blades also have a long lifespan for most applications.

High-speed steel blades are suitable for light use but wear out fastest when used extensively on tough materials. Choosing the right blade material can help maximize the lifespan of oscillating tool blades between replacements.

Multitools contain a variety of tools and implements, with the main tools typically being pliers, wire cutters, and knife blades. The width of the knife blades can vary between different multitools. Here are some common multitool blade widths:

-Slim/Pointed Blade – Approximately 1/2 inch wide or less. Many multitools have a slim or pointed blade optimized for more delicate tasks like opening packages, cutting thread, etc. The narrow profile makes them less useful for heavy-duty cutting.

So in summary, blade widths on full-size multitools tend to range from 1/2-inch slim blades up to 1 1/2-inch saws, with the most common being a 3/4-inch plain or serrated knife blade. Compact multitools usually have thinner blades under 1/2 inch. The variety of widths and styles provides cutting options for many situations.

Multitool blades come in a variety of Teeth Per Inch (TPI) configurations to suit different cutting tasks. The TPI determines the size and spacing of the teeth on the blade and affects its cutting ability:

Unlike a regular saw blade, which has large gullets between each tooth for clearing sawdust, the teeth on a Japanese teeth blade have minimal gullets. This enables the blade to cut smoothly and cleanly while removing only tiny chips of material.

The offset tooth pattern also reduces vibration and chatter compared to blades with standard tooth profiles. This makes the Japanese teeth blade ideal for intricate and detailed cuts in materials where you want a smooth edge and high precision.

So in summary, the key characteristics of a Japanese teeth oscillating blade are the tiny, overlapping offset teeth, which enable detailed curved and scroll cuts with reduced vibration. The distinctive tooth design is how it gets its name.

The shape of a multitool blade impacts its cutting ability and versatility. Multitool blades come in several common shapes, each suited for particular tasks:

Considering the blade shape in addition to size and TPI allows you to select the perfect multitool blade for the materials and cuts required. The variety of specialized blade shapes maximizes the versatility of any multitool.

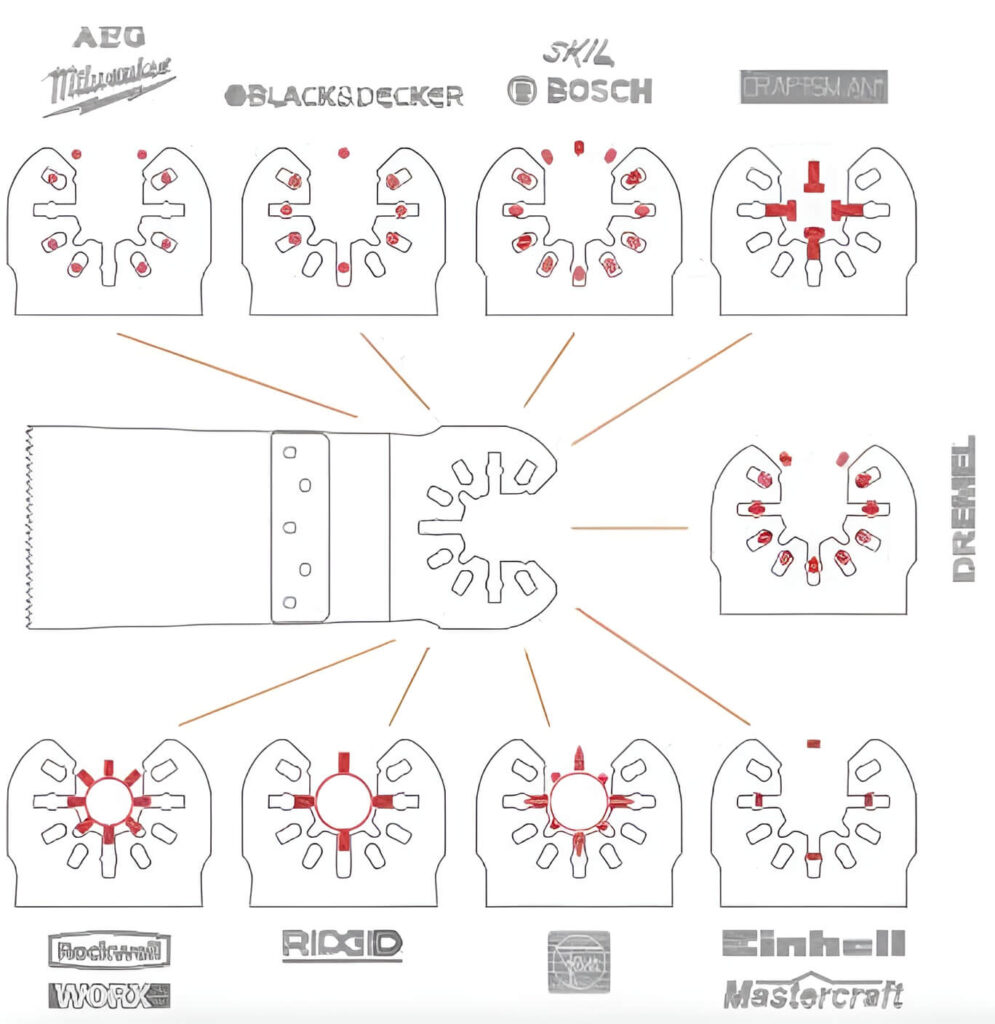

The most common universal fitting system is the U-shaped interface, with holes spaced 4mm apart. Major power tool companies like DeWalt, Milwaukee, Bosch and Rockwell all use this U-shank system for their oscillating multi-tools.

This opens up a wide selection of aftermarket and speciality blades that can be fitted to these popular tools. Users aren’t limited only to what the power tool company offers.

Some exceptions are Fein and Porter-Cable, which use proprietary blade interfaces only compatible with their respective tools. This means you can only use blades designed for Fein with a Fein oscillating tool. So, it’s important to check for compatibility if switching between tool brands.

While the major players utilize the universal fit, there can still be minor differences in blade connections. For example, Bosch and Rockwell blades tend to have a tighter fit than some competitors. This may require a bit more effort mounting or unmounting, but it doesn’t affect performance.

There are a few main types of oscillating blade locking mechanisms used on tools like multi-tools and jigsaws:

– Lever Lock – A switch or lever that needs to be manually activated to lock or unlock the blade. This is a very common and simple mechanism.

– Tool-Free Lock – The blade is secured in place magnetically or with a quick insert system without needing tools. This allows quick blade changes.

– Twist Lock – The blade needs to be twisted into the locked position. A button may need to be held while twisting.

– Collet Lock – A collet tightens around the blade shank to hold it in place. This provides very secure clamping.

– Ball Bearing Lock – Steel ball bearings grip into the blade shank through tension to hold the blade.

The most common oscillating blade locking system is probably the lever lock. It provides a good balance of security, ease of use, and low cost. Tool-free locks are also becoming more popular for convenience, but lever locks tend to still be the most prevalent.

Yes, a good quality oscillating multi-tool with the proper metal cutting blade can cut through thin to moderately thick sheet metal, steel rods, pipes, nails, screws and other metal materials. Look for bi-metal or carbide-tipped blades for the best metal cutting performance.

Starlock is a proprietary accessory blade attachment system designed by Fein. Starlock blades have a three-point mounting interface that creates a more secure and rigid blade connection to the oscillating tool compared to standard universal fit blades. The sturdy interface allows Starlock blades to transfer higher cutting power.

Oscillating tools are not ideal for cutting bolts or nails flush to a surface. While a multi-tool with a metal cutting blade may be able to cut through small nail shafts or the threaded section of a bolt, it lacks the cutting force to make smooth, flush cuts. For that task, use bolt/nail-cutting pliers.

It is not recommended to try sharpening your own oscillating tool blades. The complex tooth geometry and precise machining of quality blades are difficult to reproduce.

Quickly replacing a worn or damaged blade is better than risking improper sharpening. Many carbide and diamond grit blades are designed to maintain sharpness so sharpening is unnecessary.